ASME SB209 Aluminium Checkered Plates Stockist in Coimbatore, Aluminium Plates Supplier in Coimbatore, Aluminium Plates in Coimbatore.

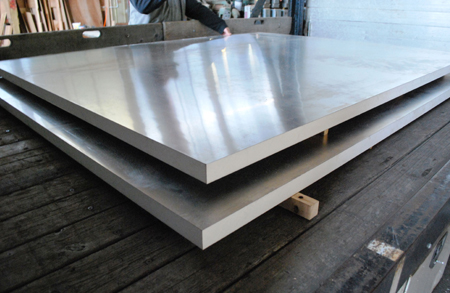

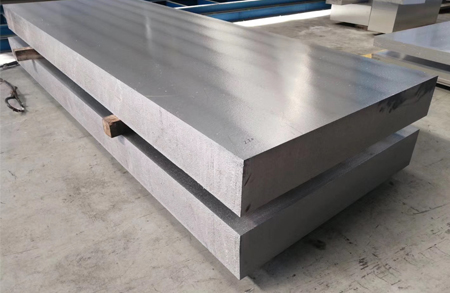

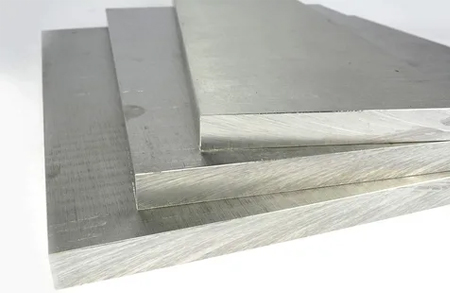

Jagdish Metal is a prominent Aluminium plate exporter and supplier in Coimbatore, renowned for delivering high-quality aluminum solutions to cater to different industrial requirements. Aluminium plates refer to flat-rolled products whose thickness is more than 6mm and provide excellent strength, durability, and corrosion resistance. We provide aluminium plates in various grades, such as 1100, 3003, 5052, 6061, and 7075, with 6061 being one of the most sought-after options due to its superior machinability and mechanical properties. With years of experience, we accurately produce plates to suit various applications, providing maximum performance and reliability. As an ISO 9001:2008 certified company, we take pride in delivering products that meet global standards.

Our aluminium plates are available in different specifications to meet customer requirements. The thickness varies from 4mm to 25mm, offering flexibility for various industrial applications. The width ranges from 1200mm to 2500mm, and the length from 2400mm to 12000mm, with choices for custom lengths. We have various finishes such as Mill finish, customer-specific finish, and bright finish, allowing clients to select the most suitable surface for their projects. Our aluminium plates are crafted with precision and quality, ensuring they meet the rigorous demands of the construction, manufacturing, and engineering sectors.

Aluminium plates are used in many applications due to their excellent properties. They are used in construction, automotive, aerospace, marine, and industrial applications where strength and lightweight properties are required. It is best for severe environments, while its heat conductivity facilitates its use in heat exchangers and refrigerators. Its fine machinability, and weldability also make it a popular material for structural and fabrication applications. We make sure that every aluminium plate is of the best durability and performance.

Our aluminium plates undergo rigorous quality checking, including ultrasonic inspection, mechanical inspection, and corrosion resistance testing, to ensure that they conform to international standards. Our secure packaging to avoid damage during transit and our quick transportation ensure prompt delivery. We are committed to providing high-quality aluminium plates that reflect our expertise and dedication to customer satisfaction.

Standards : ASME SB209 / ASTM B209

Temper : O, H12, H14, H16, H18, H19, H22, H24

Thickness : 0.2-300mm

Width : 500-2500mm

Length : 500-10000mm etc

Surface : Bright, polished, hair line, brush, sand blast, embossed, etching, etc.

Finish : Mill, Customer specific finish

Coating : PVC Coated, Color Coated, Polyester, Fluorocarbon, polyurethane and epoxy coating

Type : Hot-Rolled (HR) / Cold-Rolled (CR) Sheet

Available Grades : 1050, 1060, 1070, 1100, 2014, 2017, 2024, 2024 T3511, 3003, 5005, 5052, 5754, 5082, 5083, 5086, 6061, 6063, 6082, 6083, 7050, 7075

| European Standard | BS (OLD) | USA (AA) | GERMANY (DIN) | ISO | IS | Canadian |

|---|---|---|---|---|---|---|

| EN AW-1050 A | 1E | 1050 | Al99.5 | Al99.5 | 19500, 19501 | 1 S |

| EN AW-1070 A | – | 1070 | Al-99.7 | Al-99.7 | 19700 | – |

| EN AW-1100 | IC | 1100 | Al-99.0 | Al-99.0 | 19000 | 2 S |

| EN AW-2011 | FC1 | 2011 | AlCuBiPb | AlCu6BiPb | – | 28S |

| EN AW-2014 | HE15 | 2014 | AlCuSiMn | AlCu4SiMg | 24345 | B26S |

| EN AW-2024 | – | 2024 | AlCuMg2 | AlCu4Mg1 | – | 24 S |

| EN AW-3003 | N3 | 3003 | AlMnCu | AlMn1Cu | 31000 | 3 S |

| EN AW-3103 | – | 3103 | – | AlMn1 | – | – |

| EN AW-6101A | E91E | 6101 | E AlMgSi 0.5 | E AlMgSi(A) | 63401 | D50S |

| EN AW-6005 | – | 6005 | AlMgSi0.7 | AlSiMg | 62400 | C51S |

| EN AW-6351 | HE30 | 6351 | AlMgSi1 | AlSiMg0.5Mn | 64430 | B51S |

| EN AW-6060 | – | 6060 | AlMgSi 0.5 | AlMgSi | – | – |

| EN AW-6061 | HE20 | 6061 | AlMgSiCu | AlMg1SiCu | 65032 | 65S |

| EN AW-6063 | HE9 | 6063 | AlMgSi0.5 | AlMg0.7Si | 63400 | 50S |

| EN AW-6082 | HE30 | 6351 | AlMgSi1 | AlSi1MgMn | 64430 | B51S |

| Alloy | Si % | Mg % | Mn % | Cu % | Fe % | Cr % | Zn % | Ti % | Others % | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| EN AW-1050 A | 0.25 Max | 0.05 Max | 0.05 Max | 0.05 Max | 0.40 Max | – | 0.07 Max | 0.05 Max | – | 99.5 Min |

| EN AW-1070 A | 0.20 Max | 0.03 Max | 0.03 Max | 0.03 Max | 0.25 Max | – | 0.07 Max | 0.03 Max | – | 99.7 Min |

| EN AW-1100 | Si+Fe 0.95 Max | – | 0.05 Max | 0.05 – 0.20 | – | – | 0.10 Max | 0.05 Max | – | 99.0 Min |

| EN AW-2011 | 0.40 Max | – | – | 5.00 – 6.00 | 0.70 Max | – | 0.30 Max | – | Bi: 0.20 – 0.60 Pb: 0.20 – 0.60 |

Remainder |

| EN AW-2014 | 0.50 – 1.20 | 0.20 – 0.80 | 0.40 – 1.20 | 3.90 – 5.00 | 0.70 Max | 0.10 Max | 0.25 Max | 0.15 Max | – | Remainder |

| EN AW-2024 | 0.50 Max | 1.20 – 1.80 | 0.30 – 0.90 | 3.80 – 4.90 | 0.50 Max | 0.10 Max | 0.25 Max | 0.15 Max | 0.15 Max | Remainder |

| EN AW-3003 | 0.60 Max | – | 1.00 – 1.50 | 0.05 – 0.20 | 0.70 Max | – | 0.10 Max | – | 0.15 Max | Remainder |

| EN AW-3103 | 0.50 Max | 0.30 Max | 0.90 – 1.50 | 0.10 Max | 0.70 Max | 0.10 Max | 0.20 Max | 0.10 Max | – | Remainder |

| EN AW-6101A | 0.30 – 0.7 | 0.40 – 0.90 | 0.03 Max | 0.05 Max | 0.40 Max | – | – | – | 0.10 Max | Remainder |

| EN AW-6005 | 0.60 – 0.90 | 0.40 – 0.60 | 0.10 Max | 0.10 Max | 0.35 Max | 0.10 Max | 0.10 Max | 0.10 Max | – | Remainder |

| EN AW-6351 | 0.70 – 1.30 | 0.40 – 0.80 | 0.40 – 0.80 | 0.10 Max | 0.50 Max | – | 0.20 Max | 0.20 Max | 0.15 Max | Remainder |

| EN AW-6060 | 0.30 – 0.60 | 0.35 – 0.60 | 0.10 Max | 0.10 Max | 0.10 – 0.30 | 0.05 Max | 0.15 Max | 0.10 Max | – | Remainder |

| EN AW-6061 | 0.40 – 0.80 | 0.80 – 1.20 | 0.15 Max | 0.15 – 0.40 | 0.70 Max | 0.04 – 0.35 | 0.25 Max | 0.15 Max | – | Remainder |

| EN AW-6063 | 0.20 – 0.60 | 0.45 – 0.90 | 0.10 Max | 0.10 Max | 0.35 Max | 0.10 Max | 0.10 Max | 0.10 Max | – | Remainder |

| EN AW-6082 | 0.70 – 1.30 | 0.60 – 1.20 | 0.40 – 1.00 | 0.10 Max | 0.50 Max | 0.25 Max | 0.20 Max | 0.10 Max | – | Remainder |

| Alloy | Temper | UTS (MPa) Min |

UTS (MPa) Max |

Yield Strength (MPa) Min |

Yield Strength (MPa) Max |

Elongation % (A50mm Min) |

|---|---|---|---|---|---|---|

| EN AW-1050 A | F | 60 | – | 20 | – | 23 |

| EN AW-1050 A | O | 60 | 95 | 20 | – | 23 |

| EN AW-1070 A | F | 60 | – | 20 | – | 23 |

| EN AW-1100 | O | 75 | 110 | – | – | 25 |

| EN AW-2011 | T4 | 275 | – | 125 | – | 12 |

| EN AW-2011 | T6 | 310 | – | 230 | – | 6 |

| EN AW-2014 | O | – | 250 | – | 135 | 10 |

| EN AW-2014 | T4 | 370 | – | 230 | – | 11 |

| EN AW-2014 | T6 | 415 | – | 370 | – | 5 |

| EN AW-2024 | O | – | 250 | – | 150 | 10 |

| EN AW-2024 | T3, T3510, T3511 | 395 | – | 290 | – | 6 |

| EN AW-2024 | T8, T8510, T8511 | 455 | – | 380 | – | 4 |

| EN AW-3003 | F | 95 | – | 35 | – | 20 |

| EN AW-3003 | O | 95 | 135 | 35 | – | 20 |

| EN AW-3103 | F | 95 | – | 35 | – | 20 |

| EN AW-3103 | O | 95 | 135 | 35 | – | 20 |

| EN AW-6101A | T6 | 200 | – | 170 | – | 8 |

| EN AW-6005 | T4 | 180 | – | 90 | – | 13 |

| EN AW-6005 | T6 | 270 | – | 225 | – | 6 |

| EN AW-6351 | O | – | 160 | – | 110 | 12 |

| EN AW-6351 | T4 | 205 | – | 110 | – | 12 |

| EN AW-6351 | T6 | 290 | – | 250 | – | 6 |

| EN AW-6060 | T4 | 120 | – | 60 | 14 | 12 |

| EN AW-6060 | T5 | 160 | – | 120 | – | 6 |

| EN AW-6060 | T6 | 190 | – | 150 | – | 6 |

| EN AW-6060 | T64 | 180 | – | 120 | – | 10 |

| EN AW-6060 | T66 | 215 | – | 160 | – | 6 |

| EN AW-6061 | O | – | 150 | – | 110 | 14 |

| EN AW-6061 | T4 | 180 | – | 110 | – | 13 |

| EN AW-6061 | T6 | 260 | – | 240 | – | 6 |

| EN AW-6063 | O | – | 130 | – | – | 16 |

| EN AW-6063 | T4 | 130 | – | 65 | – | 12 |

| EN AW-6063 | T5 | 175 | – | 130 | – | 6 |

| EN AW-6063 | T6 | 215 | – | 170 | – | 6 |

| EN AW-6063 | T66 | 245 | – | 200 | – | 6 |

| EN AW-6082 | O | – | 160 | – | 110 | 12 |

| EN AW-6082 | T4 | 205 | – | 110 | – | 12 |

| EN AW-6082 | T5 | 270 | – | 230 | – | 6 |

| EN AW-6082 | T6 | 290 | – | 250 | – | 6 |